On October 11 the next International Exhibition of Equipment, Machines and Ingredients for the Food and Processing Industry AGROPRODMASH 2019 came to an end.

This year APM UpakMash Salon “Packaging equipment and materials. Dosage, packaging, labeling” was filled with advanced technologies — exhibitors demonstrated robotics, automation of production processes, as well as smart solutions in the packaging and packaging segment.

The stand of the company с was no exception. All demonstrated equipment AMATA already in the basic version has the ability to integrate into various systems of control and automation of production. In addition, automatic statistics collection with the ability to connect remotely allows you to quickly and easily configure remote control of production processes.

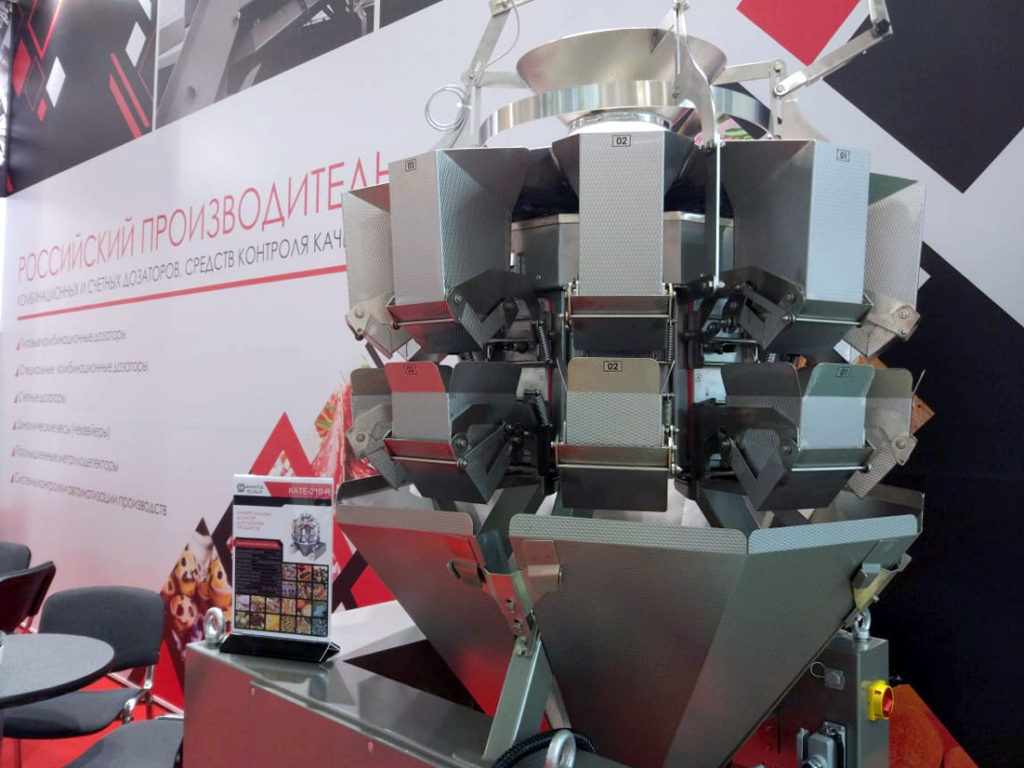

According to a long tradition, samples of all the lines of manufactured equipment were demonstrated at the AMATA stand.

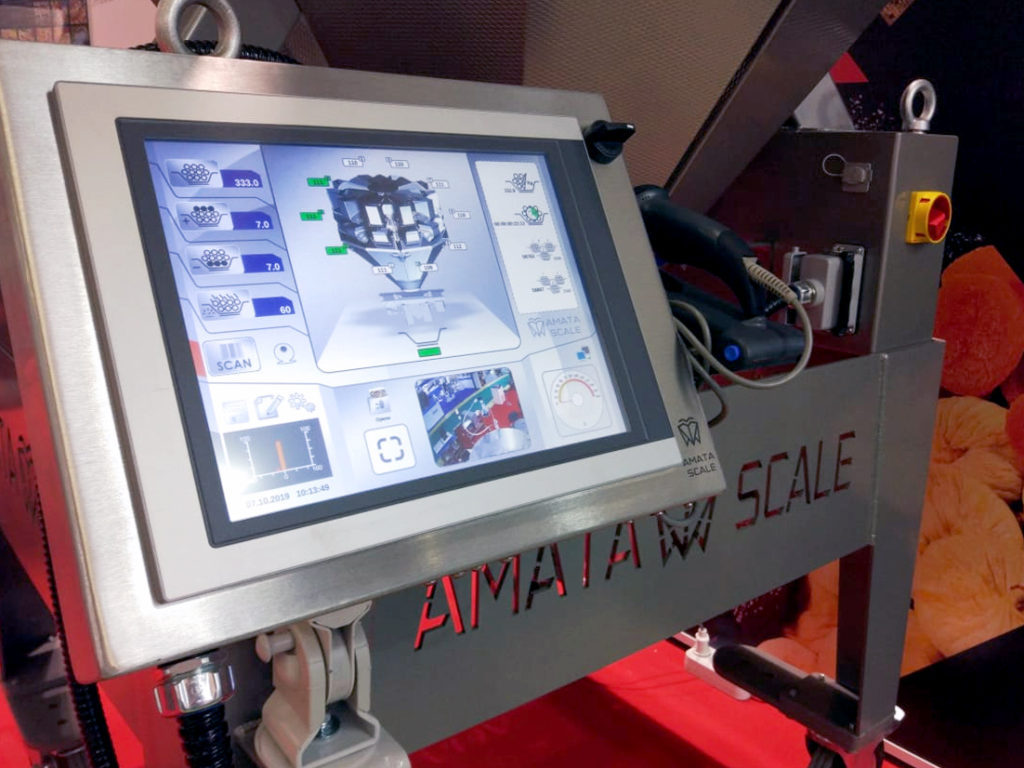

The line of combination weighing was presented by KATE-210-R typical multihead weigher, which was already loved by customers, with 10 weight pockets and a kinematic capacity of 70 packs per minute. This well-known dispenser is perfect for most dry bulk products: pasta, cereals, sweets, gingerbread, cookies, crackers, coffee beans, nuts, snacks, chips and so on. In a grooved design, this multihead is ideal for frozen foods: dumplings, dumplings, nuggets, frozen vegetables and fruits.

The booth guests praised the technical performance of the dispenser, as well as user-friendly software with an original interface. Visitors especially liked the online camera installed on the dispenser, which allows the operator to see the packaging process in real time right on the control panel.

The direction of the control equipment was presented by a checkweigher-metal detector AMATA-CW-MD. In recent years, this direction has been actively developed and has become a priority for most large food industries, since an additional check of both raw materials and the finished product for the presence of metal particles allows this product to be really safe, and controlling the weight of the product in the finished packaging simplifies working with network retail.

A checkweigher with a tape width of 250 mm, equipped with a metal detector frame, was presented at the exhibition. The kinematic productivity of such a line is up to 100 packs per minute.

Development Director of AMATA SCALE Anastasia Nevolina noted:

We believe that the demand for quality control equipment will only grow every year. Already now we can see how customers are purchasing from us a second, third, fourth line for product quality control, which includes both metal detectors and checkweighers.

Without such equipment, working with network retail is simply impossible. And the current trend of stricter requirements for food quality imposes even greater responsibility on manufacturers, including within the framework of the adopted Strategy for improving the quality of food products in the Russian Federation until 2030. We will not stand still, our plans include expanding the range of control equipment, as well as equipping our machines with new convenient and useful functionality.

Also this year, we presented a novelty in the field of packaging – the counting dispenser AMATA-MILITA-305, which does not work by weight, but by count. Now our customers can carry out piece packing of sweets, dragees, lozenges, mozzarella balls, sausages and so on. The AMATA-MILITA-305 dispenser was demonstrated in action – right at the stand he packed up marmalade in chocolate icing, 10 pieces in each jar. The kinematic performance of the dispenser is 50 cycles per minute.

AMATA SCALE Commercial Director Darius Navickas said:

To be honest, we did not expect such a stir around our new counting dispenser. Some guests of the exhibition purposefully came to look at this particular dispenser, to find out its characteristics, to see how it works. We already have several requests for this type of dispenser. We will work on them. We hope that demand will only grow, because this type of dispenser is very rare in the Russian market.

It should also be noted that all AMATA equipment is manufactured in Russia. We have our own production facilities, an experienced design office and an operational after-sales service.

If you were unable to visit the AMATA SCALE during the exhibition, you can always get advice from our managers by phone: +7 (812) 320-42-01 or write to us: info@amatascl.com.