Penne, fusilli, rigate, conchiglioni, casarecce, farfalle — eyes run up from a variety of pasta on store shelves. Formerly many years ago it was a sumptuous dessert, nowadays it is rightfully the most popular product, without which not a single Russian family can do. Moreover, if previously pasta was not considered the most wholesome food and was not recommended to people who are on a diet, now they are gradually gaining the status of a healthy product, thanks to the fashion for Italian cuisine. The pace of pasta production is constantly growing, and the variety of forms of pasta itself is constantly updated with interesting new products

What can the AMATA team offer for pasta producers? In this article we will talk about both standard solutions and the latest packaging and packaging innovations that will be useful and relevant on the production sites of any pasta factory.

DOSING PASTA: EXACTLY AND QUICKLY

For pasta dosing we recommend using our universal combination dispensers KATE-210-R or KATE-214-R. These are solutions that have been tested by time and by dozens of our customers throughout Russia. Their versatility lies in the fact that on one multihead you can pack different types of bulk products, in our case, different types of pasta.

These models of AMATA combinational dispensers are typical, therefore their production time is short and the price is reasonable. Most pasta producers choose these options. Moreover the basic models already include useful options: collecting, saving and displaying statistics, the ability to connect to production automation systems, choosing a recipe for a barcode, and the presence of an online camera in the product download area.

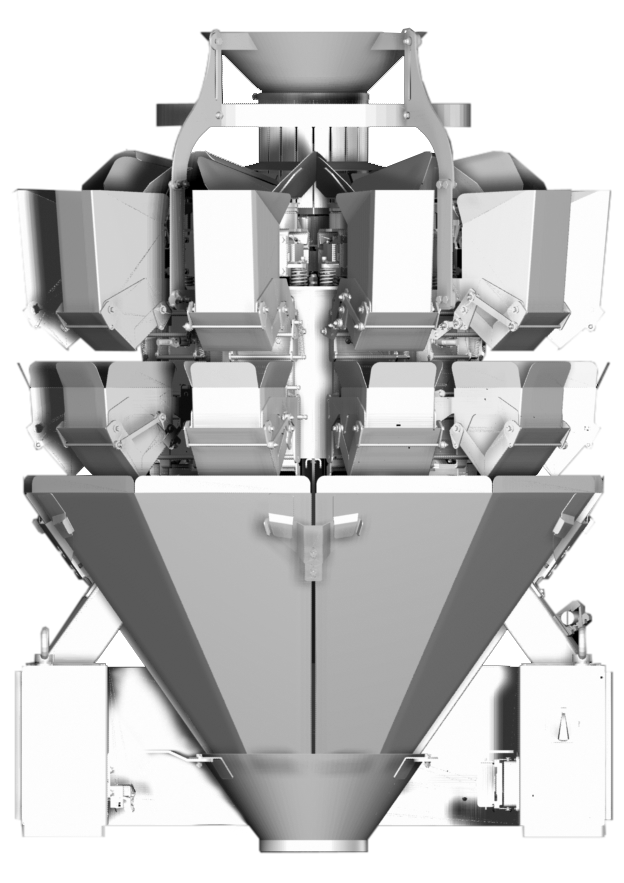

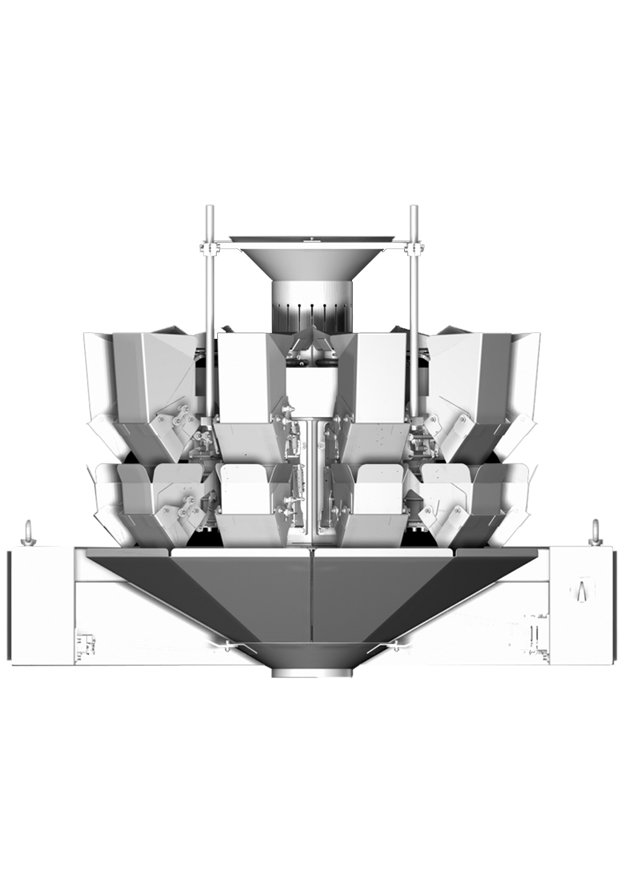

Radial combination weigher (Multihead) KATE-210-R contains 10 weight pockets, which allows it to achieve a productivity of up to 70 doses / min.

This combination dispenser is in great demand among small industries, because it perfectly combines the price-quality ratio. In addition, the small size allows you to use the specified dispenser in a limited space of a small packaging workshop.

At the same time, it is a full-fledged industrial dispenser that is capable of generating a final dose of up to 1.5 kg per discharge.

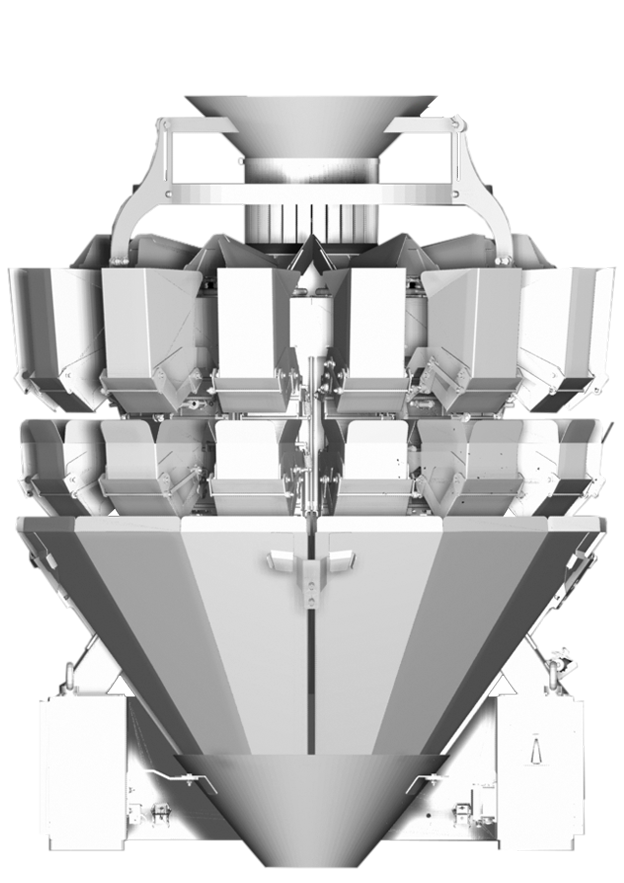

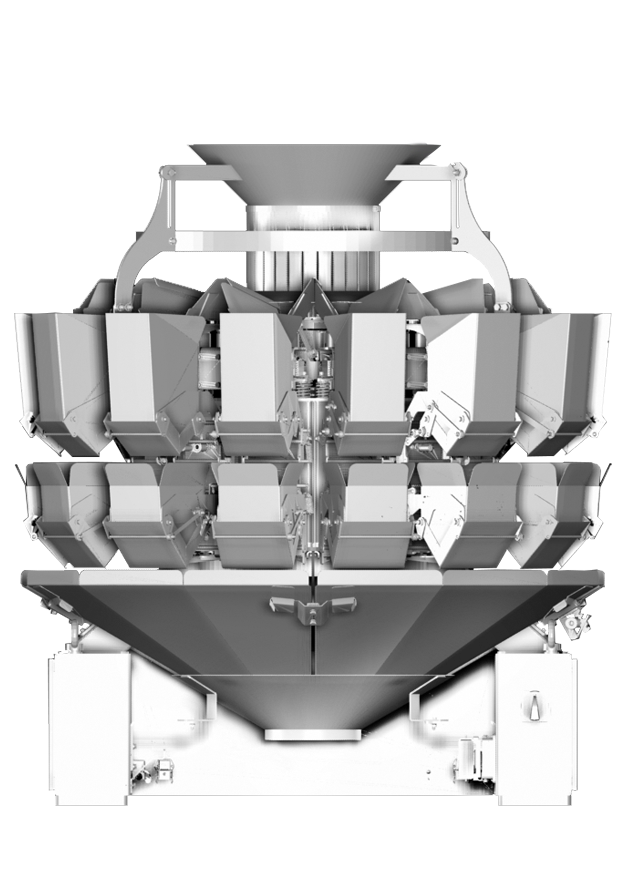

Radial combination weigher (Multihead) KATE-214-R dispenser contains 14 weight pockets, which allows you to quickly create a combination of the final dose compared to the previous model. Thus, it is a faster dispenser, its kinematic productivity is up to 140 doses / min.

The remaining technical parameters of this multihead are similar to those of the KATE-210-R model.

The specified industrial dispenser is the most popular due to its increased productivity and reasonable cost. Most medium and large manufacturers choose this particular model.

DOSING PASTA MORE FASTER

If you need faster models with increased performance, pay attention to the multihead AMATA with an increased number of weight baskets — KATE-220-R or KATE-228-R. These models of combination dispensers are designed on the basis of standard AMATA multiheads, however, due to the increased number of weight pockets, the selection of the combination of the final dose is faster than with standard models.

In addition these combination dosing models can be used with two packaging machines at the same time. This is very convenient if there are high-speed lines in the production: two packaging machines (or one twin double-strapped packaging machine) can produce two batches of product in parallel, with only one combination dispenser being used. This saves space, money and maintenance time of the dispenser.

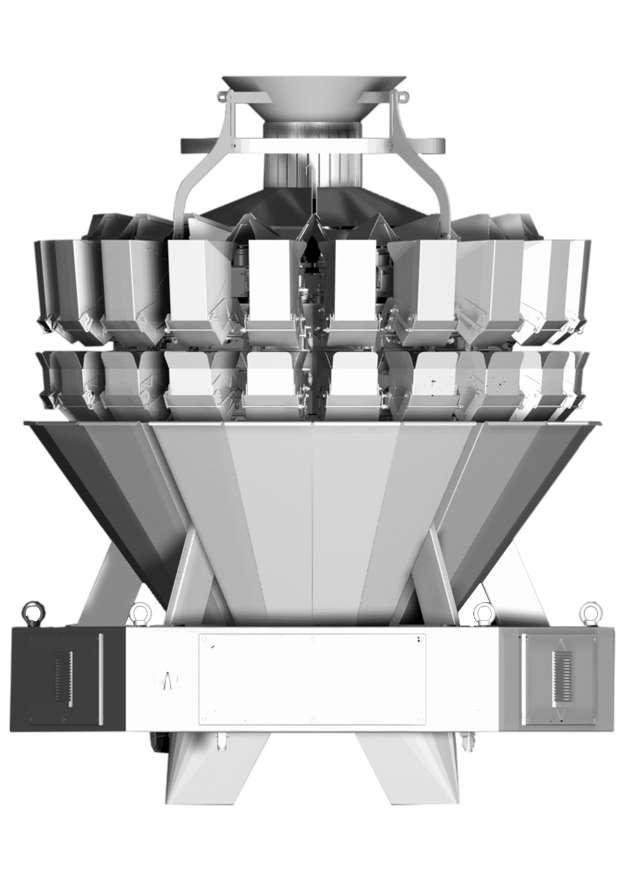

Radial combination weigher (Multihead) KATE-220-R with 20 weight pockets that deliver up to 140 doses / min.

In case of use with two packaging machines, the specified multihead works in a special mode – 10 weight pockets work from each of the packaging racks. In this case, the performance of this combination dispenser is up to 2×70 doses / min, i.e. up to 70 doses / min for each stream.

Radial combination weigher (Multihead) KATE-228-R with 28 weight pockets that deliver up to 240 doses / min.

This is a high-speed combination dispenser that is suitable for filling all kinds of short pasta.

In the case of use with two packaging machines, the specified multihead works in a special mode — 14 weight pockets work from each of the packaging racks. In this case, the performance of this combination dispenser is up to 2×120 doses / min.

SPECIAL MODELS FOR DOSING PASTA

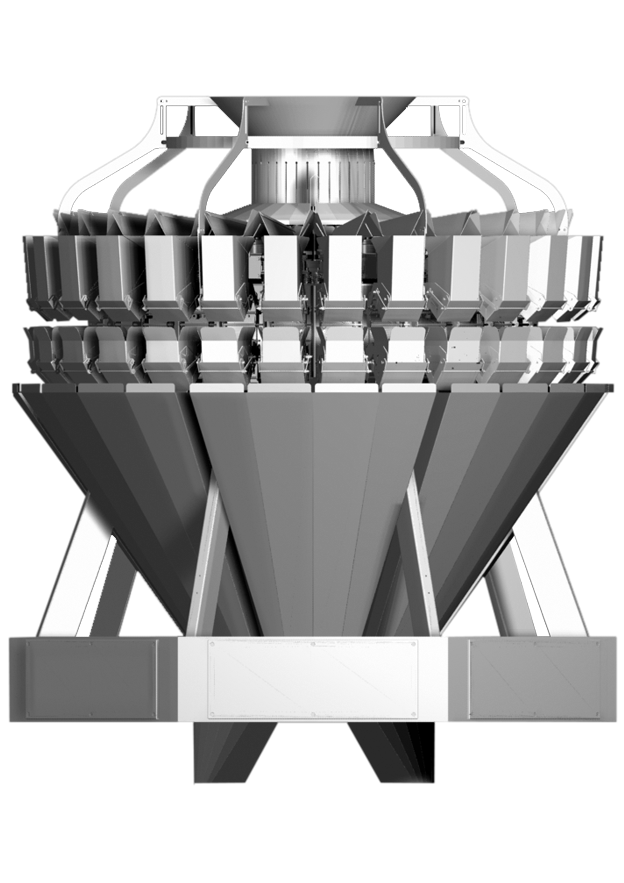

In addition to the proposed solutions for pasta packing, the AMATA team brings to your attention our special combination dispensers — KATE-210-R30 or KATE-214-R30. The discharge slopes of these multihead dispensers are made with a slope of 30 degrees instead of the standard 55.

These dispensers are optimal in two main cases. In the first case, it is the packaging of fragile pasta. Thanks to the gentle slopes, the height of the product falling from the weight baskets to the synchronization hopper is reduced, which avoids mechanical damage to the fragile product. Moreover, if necessary, the discharge slopes can be additionally equipped with overlays of damping materials, which are designed for more delicate packaging. In the second case, this is a lack of space in the packaging workshop. Flat sloping ramps reduce the overall dimensions of the entire dispenser. Due to this, such multiheads are convenient to use in workshops with low ceilings or lack of space for the installation of the packaging line.

Radial combination weigher (Multihead) KATE-210-R30 with 10 weight pockets and capacity up to 60 doses / min.

This multihead can fully replace the standard 10-pocket combinational dispenser KATE-210-R. She is also able to form a final dose of up to 1.5 kg per discharge. At the same time, due to gently sloping stingrays, it takes up less space and is able to delicately pack fragile types of pasta.

All options that are included in the base of the industrial dispenser KATE-210-R are also present in this model.

Radial combination weigher (Multihead) KATE-214-R30 with 14 weight pockets and capacity up to 90 doses / min.

This multihead was designed on the basis of the standard model KATE-214-R. The main structural difference is the angle of inclination of the discharge slopes, which reduces the overall dimensions of the dispenser and ensures accurate packaging of fragile pasta.

All options that are included in the base of the industrial dispenser KATE-214-R are also present in this model.

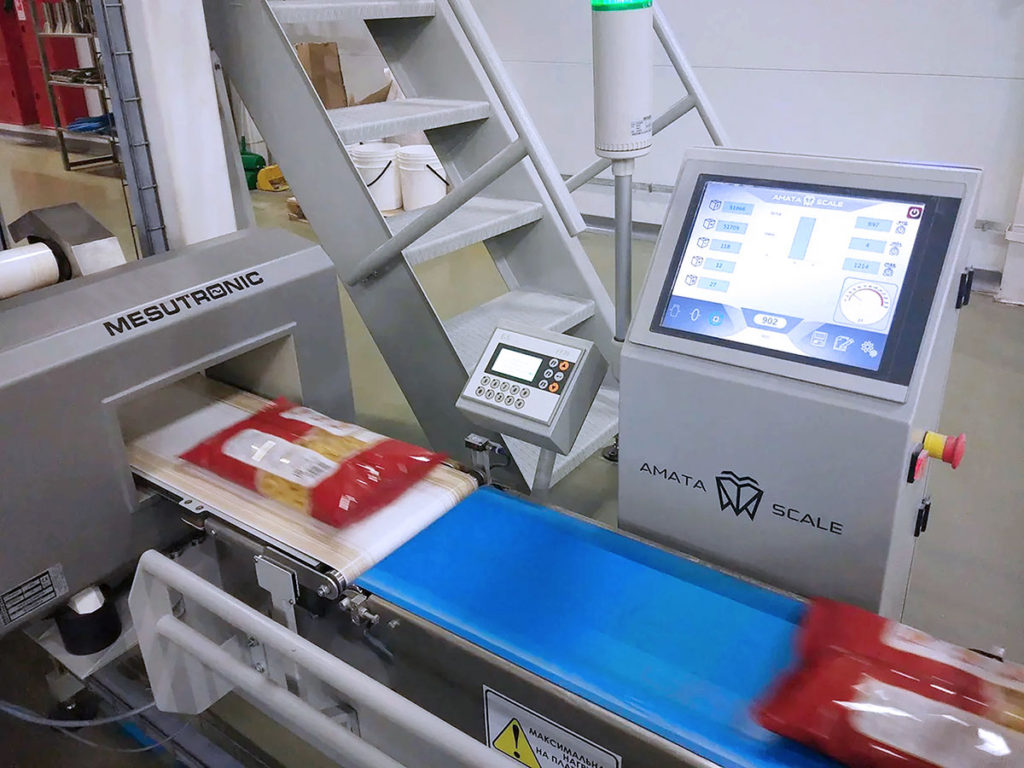

WE CONTROL WEIGHT IN PASTA PACKS

In order to exercise additional control over packaged products, we recommend equipping your production with dynamic scales (checkweigher). This is especially true when working with network retail, when there are strict requirements for the quality of the product and its packaging.

As usual a checkweigher is placed at the exit of the packaging line before group packaging. This device is designed to control the weight of pasta packages. Overweight or underweight packages are rejected, and packages of normal weight are moved to the group package unit.

The company AMATA SCALE produces a large variety of dynamic scales. Two models are basic and the remaining models are made to a specific customer request. AMATA equipment can be equipped with a rejector of any type: flipper, pusher or dropper. The rejector design is selected based on the characteristics of a particular product and its packaging.

All AMATA checkweighers have the ability to collect, store and view statistics. In each model there is a function of connecting equipment to a production automation system for remote monitoring of all parameters of dynamic scales and operational control of production processes.

CHECKING PACKAGES WITH PASTA IN THE METAL CONTENT

For additional control of ready packaged packs with pasta for the presence of metal particles in them, we recommend equipping your production with an industrial metal detector. Checking the product for the presence of foreign inclusions can improve the quality of products and ensure its safety, which in turn determines the image of the enterprise.

The principle of operation of industrial metal detectors is similar to the principle of operation of dynamic scales. A packet of pasta moves through the frame of the metal detector, where the presence of metal particles in the product is checked. Packages with metal are rejected, and packages without metal are moved to a group package.

In addition to checking the final product, we also recommend checking the input raw materials such as flour. Firstly, this allows us to identify unscrupulous suppliers at the initial stage and to carry out prompt replacement of raw materials. Secondly, the purity of the raw materials ensures the correct operation of the equipment of the processing line.

We produce a wide range of industrial metal detectors AMATA. Four models are basic, they differ in the size of the window of the metal detector frame depending on the size of the product being monitored. In addition to the basic models, AMATA SCALE also produces industrial metal detectors for a specific order of a particular production.

Among the assortment of AMATA control equipment it is worth noting dynamic scales equipped with a metal detector. These are two control elements in one piece of equipment. As a rule, such equipment is additionally equipped with a sorter, which performs separate rejection – by weight and by metal.

We collected more detailed information on the purpose, types and features of the operation of AMATA metal detectors with the article “What is a metal detector?”.

TECHNICAL ADVICE AND CAPABILITY OF TEST DRIVING

If you have any questions or are in doubt about the type of equipment you need, contact AMATA specialists. Our technical engineers carry out consultations both on general issues and the selection of specific equipment that is most optimal in a particular case.

Moreover, a policy of preliminary testing of equipment on the customer’s product was introduced for our potential customers. In other words, by prior request, we conduct a “test drive” of AMATA equipment on a specific product in order to take into account all the features of this product and determine which particular filling or control machine will be the most optimal.

Today, large enterprises for the production of pasta trust us, AMATA equipment successfully works in dozens of domestic enterprises. We invite you to become a part of the world of AMATA. AMATA SCALE specialists will select the optimal filling and control equipment specifically for your production and for your types of pasta. We will take into account all factors and requirements, features of the product and its packaging to achieve maximum results.

Contact our managers and learn more about the possibilities of AMATA equipment in the field of pasta production:

Tel: +7 (812) 320-42-01

Fax: +7 (812) 329-49-11

Email: info@amatascl.com