Linear combination weighers (Multiheads) are designed for high-precision, high-speed weighing of large fractions of heavy products or fragile and delicate products.

For fragile products

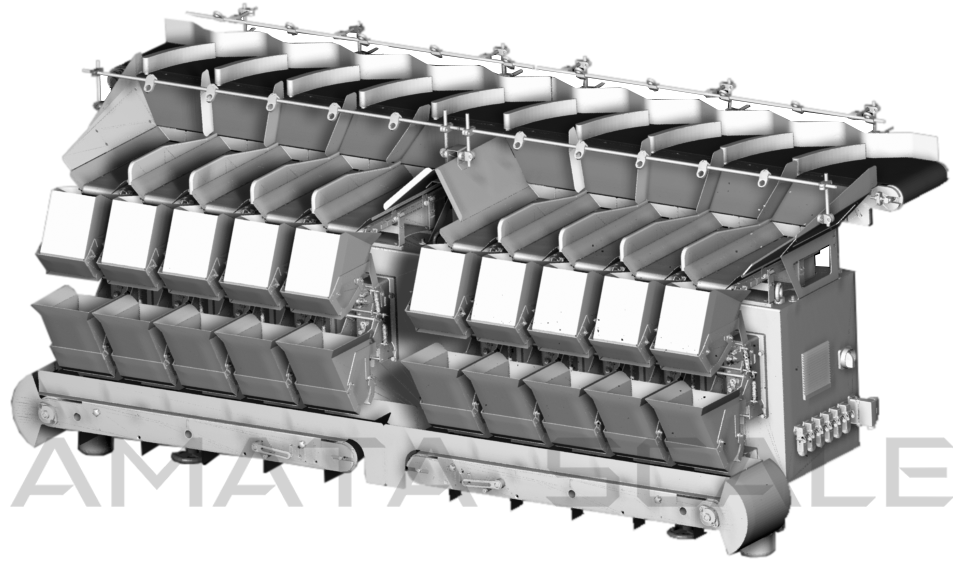

KATE-210-LT

The weight combination (Multihead) two-level KATE-210-LT dispenser of tape type with 10 weight pockets is designed for accurate dosing of medium and large-fractional products.

Ribbon construction (no vibration) allows dispensing brittle and delicate foods, such as meringues, gingerbread cakes, kurabe cookies, snacks, fragile pasta, chocolate marshmallows, breads, chips, frozen shrimps, etc.

The parts in contact with the product are made of polished stainless steel. The working surface of the conveyor belts is made of PVC. All materials used are approved for use in the food industry. If necessary, all the metal surfaces of the grocery tract can be coated with a release layer.

For ease of maintenance, the easy-detachable design of the belts of conveyor feeders, storage and weighing hoppers is provided.

| Kinematic Speed, max | 40 bpm |

| Tare, min | 0.015 kg |

| Tare, max | 1.5 kg |

| Weighing Method | Single Point Load Cell |

| Combination Accuracy | 0.1 g |

| No. of Scales | 10 pcs |

| Hopper Volume5 | 5500 cc |

| Power | AC220V 50Hz |

| Power Consumption | 2.1 kW |

| Dust/Water Protection | IP 54 |

| Outer Dimensions, not over | 1065 х 1288 х 2861 mm |

| Weight, not over | 1000 kg |

Feed Distribution Conveyor

Conveyor Feeders

Pool Hoppers

Weight Hoppers

Weighing Modules

Discharge Conveyor

Control Computer

Remote Control

Damping Overlays

Pedestal

Platform

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

DOSING MARSHMALLOW IN CHOCOLATE GLAZE:

For heavy large products

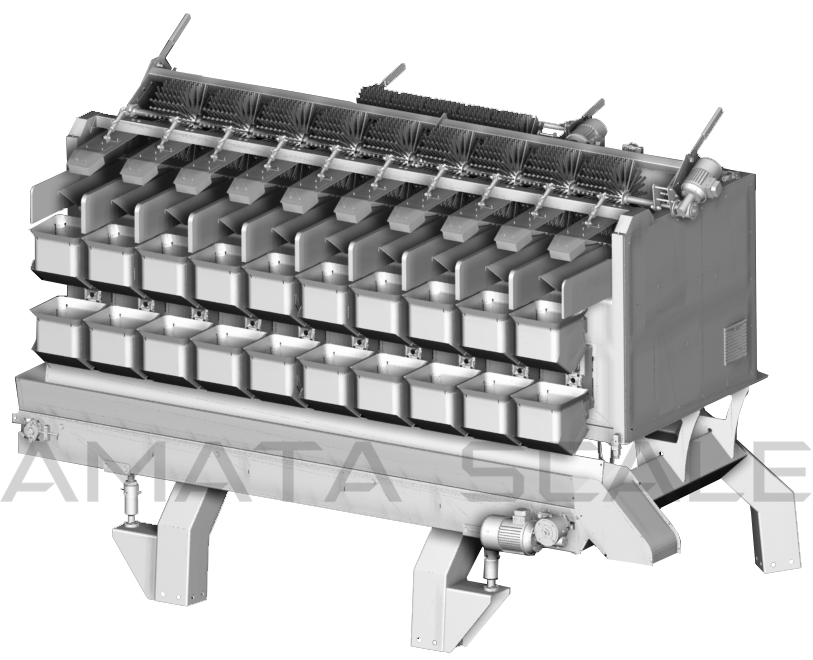

KATE-210-LV

Weight combination (Multihead) two-level dispenser KATE-210-LV with 10 weight hoppers specially designed for large agricultural products such as: potatoes, turnips, beets, onions, apples, oranges, etc. Also suitable for dispensing other large-scale products – frozen meat or fish.

Distributive brushes promote uniform loading of vibrolots. Pneumatic locks on the vibrolots exclude an arbitrary drop of the product in the accumulation hoppers.

Metal parts in contact with the product are made of polished stainless steel. All materials used are approved for use in the food industry.

For ease of maintenance, the easy-detachable design of distribution brushes, vibrating feeders, storage and weighing hoppers is provided.

| Kinematic Speed, max | 60 bpm |

| Tare, min | 0.1 kg |

| Tare, max | 5 kg |

| Weighing Method | Single Point Load Cell |

| Combination Accuracy | 0.1 g |

| No. of Scales | 10 pcs |

| Hopper Volume | 5500 cc |

| Power | AC220V 50Hz |

| Power Consumption | 4 kW |

| Dust/Water Protection | IP 54 |

| Outer Dimensions, not over | 1600 х 1110 х 2740 mm |

| Weight, not over | 900 kg |

Vibroplatform

Brush Flow Distributors

Vibration Feeders

Pool Hoppers

Weight Hoppers

Weighing Modules

Discharge Conveyor

Control Computer

Remote Control

Pedestal

Platform

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

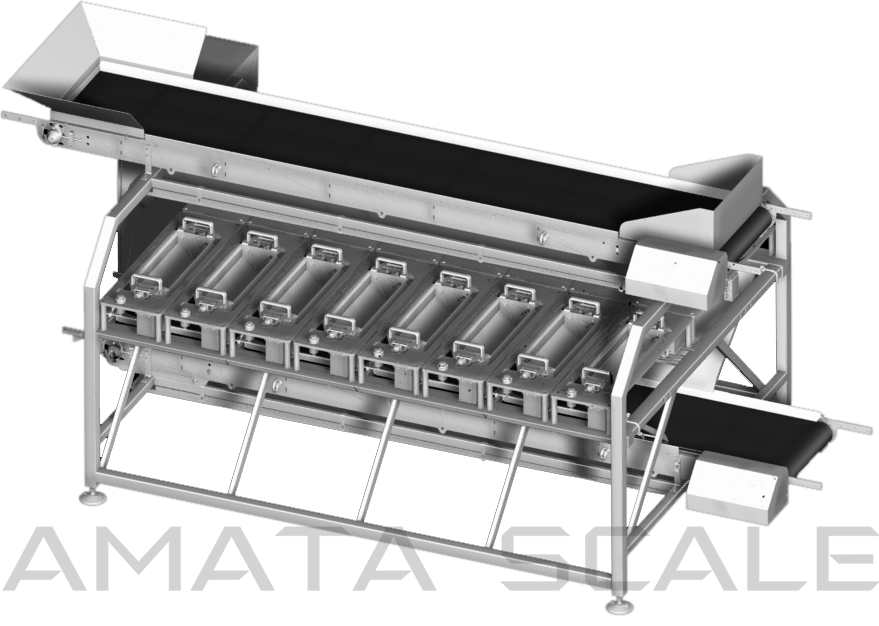

BERTHA-116-L

The semi-automatic BERTHA-116-L combination dispenser with 16 weight pockets has been specifically designed for precise dosing by weight of lumpy and piece products, such as: fish, fresh meat, large vegetables (zucchini, cucumbers, eggplants, corn), fruits (pineapples, cantaloupe, mango), etc.

The product fits into the weight hoppers by hand.

The metal parts in contact with the product are made of polished stainless steel, which is approved for use in the food industry. The surface of the weight hoppers and slopes is made corrugated. The working surface of the conveyor belts are made of PVC.

The design of the conveyors provides the possibility of its maintenance, washing and repair without complete dismantling.

| Kinematic Speed, max | 25 bpm |

| Tare, min | 0.1 kg |

| Tare, max | 5 kg |

| Weighing Method | Single Point Load Cell |

| Combination Accuracy | 0.1 g |

| No. of Scales | 16 pcs |

| Hopper Volume | 2500 cc |

| Dimensions of Fraction, not over | 450 x 130 x 60 mm |

| Power | AC220V 50Hz |

| Power Consumption | 2.4 kW |

| Dust/Water Protection | IP 65 |

| Outer Dimensions, not over | 1200 х 1844 х 2610 mm |

| Weight, not over | 900 kg |

Feed Conveyor

Weight Hoppers

Weighing Modules

Discharge Conveyor

Control Computer

Remote Control

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

DOZING FROZEN FISH: