Conveyor Metal Detectors are designed to detect extraneous metal objects in raw materials, semi-finished products and finished products.

With the help of Metal Detectors, the safety of products during processing and use is ensured, as well as the equipment is protected against ingress of random bodies containing magnetic and non-magnetic metals.

Maximum height of the controlled object: 100 mm

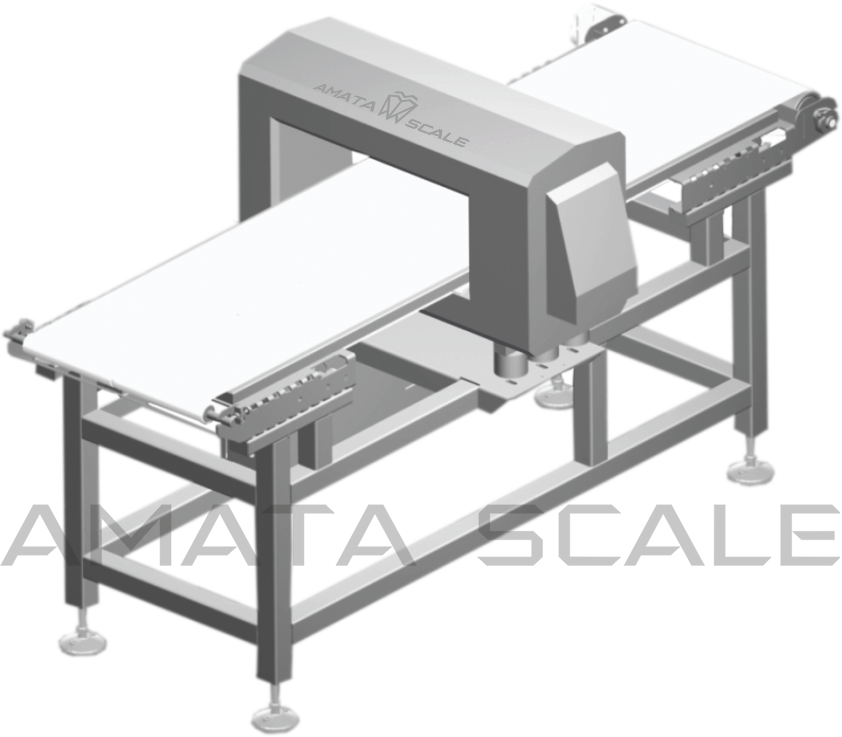

АМАТА 250MD

Conveyor metal detector is designed to detect extraneous metal objects in raw materials, semi-finished products and finished products.

The metal detector automatically scans objects on a moving conveyor belt. In the absence of metallic inclusions in the controlled product, it passes freely through the metal detector conveyor and is transferred further to the production line for further processing. Upon detection of metal objects or particles, the sound and light indication is triggered, and the object with metal is rejected.

With the help of a metal detector, the safety of products during processing and use is ensured, as well as the equipment is protected against ingress of random bodies containing magnetic and non-magnetic metals.

Various additional options can be used to receive the rejected product: a basket for collecting defects, a gravitational roller table, a rotary table, or others.

| Width of the Conveyor Belt | 250 mm |

| Height of the Controlled Object, max | 100 mm |

| Length of the Conveyor Belt | 1350 mm (without rejector) |

| Detection System | Coil |

| Detectible Material | Carbon Steel Stainless Steel Nonferrous Alloys |

| Speed of the Conveyor Belt | 50 m/min (regulated) |

| Height up to the Weigh Carriage | 720 – 950 mm |

| Power | AC220V 50Hz |

| Power Consumption | 0.5 kW |

| Dust/Water Protection | IP 54 / IP 65 |

| Version | Stainless Steel |

*The technical specifications can differ according to the product features

Grocery Conveyor

Metal Detector

Light and Sound Alarm

Rejector

Unit for Rejects Accumulation

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

WEIGHT CONTROL AND INSPECTION OF THE PRODUCT FOR METAL PARTICLES:

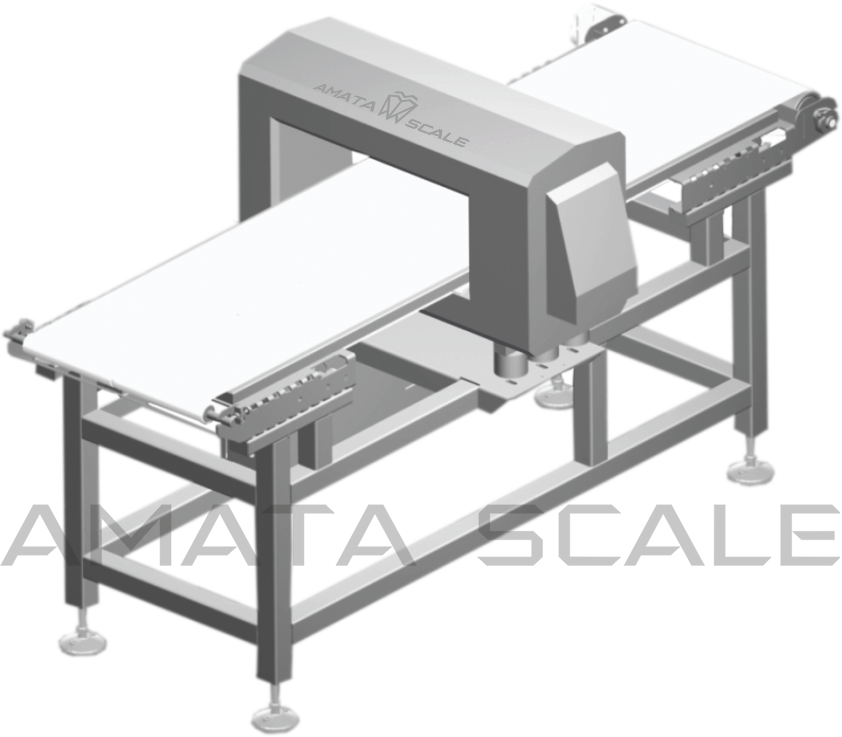

АМАТА 350MD

Conveyor metal detector is designed to detect extraneous metal objects in raw materials, semi-finished products and finished products.

The metal detector automatically scans objects on a moving conveyor belt. In the absence of metallic inclusions in the controlled product, it passes freely through the metal detector conveyor and is transferred further to the production line for further processing. Upon detection of metal objects or particles, the sound and light indication is triggered, and the object with metal is rejected.

With the help of a metal detector, the safety of products during processing and use is ensured, as well as the equipment is protected against ingress of random bodies containing magnetic and non-magnetic metals.

Various additional options can be used to receive the rejected product: a basket for collecting defects, a gravitational roller table, a rotary table, or others.

| Width of the Conveyor Belt | 350 mm |

| Height of the Controlled Object, max | 100 mm |

| Length of the Conveyor Belt | 1350 mm (without rejector) |

| Detection System | Coil |

| Detectible Material | Carbon Steel Stainless Steel Nonferrous Alloys |

| Speed of the Conveyor Belt | 50 m/min (regulated) |

| Height up to the Weigh Carriage | 720 – 950 mm |

| Power | AC220V 50Hz |

| Power Consumption | 0.5 kW |

| Dust/Water Protection | IP 54 / IP 65 |

| Version | Stainless Steel |

*The technical specifications can differ according to the product features

Grocery Conveyor

Metal Detector

Light and Sound Alarm

Rejector

Unit for Rejects Accumulation

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

WEIGHT CONTROL AND INSPECTION OF THE PRODUCT FOR METAL PARTICLES:

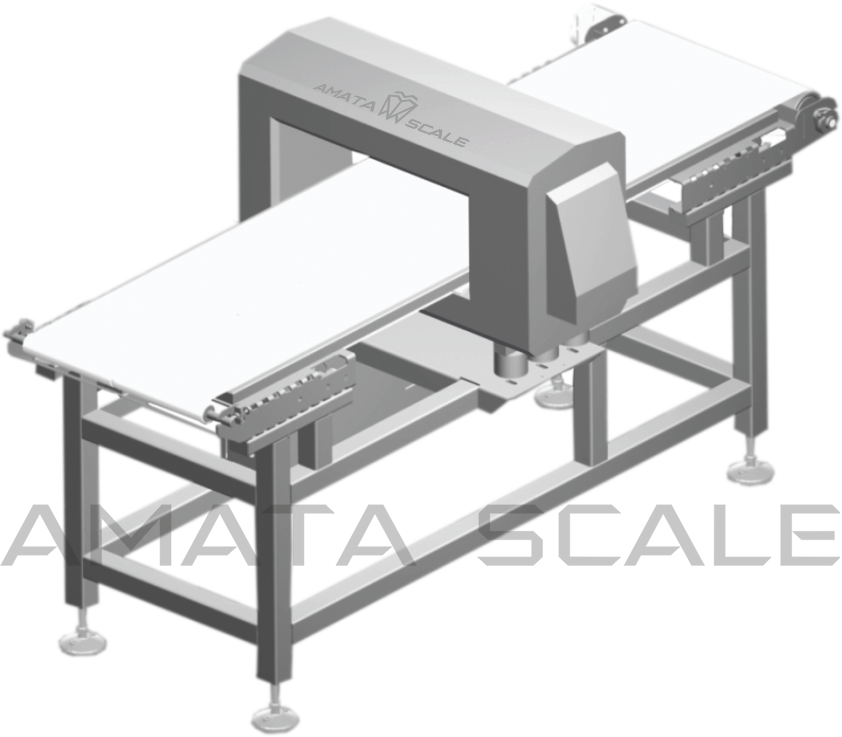

Maximum height of the controlled object: 250 mm

АМАТА 250MD

Conveyor metal detector is designed to detect extraneous metal objects in raw materials, semi-finished products and finished products.

The metal detector automatically scans objects on a moving conveyor belt. In the absence of metallic inclusions in the controlled product, it passes freely through the metal detector conveyor and is transferred further to the production line for further processing. Upon detection of metal objects or particles, the sound and light indication is triggered, and the object with metal is rejected.

With the help of a metal detector, the safety of products during processing and use is ensured, as well as the equipment is protected against ingress of random bodies containing magnetic and non-magnetic metals.

Various additional options can be used to receive the rejected product: a basket for collecting defects, a gravitational roller table, a rotary table, or others.

| Width of the Conveyor Belt | 250 mm |

| Height of the Controlled Object, max | 250 mm |

| Length of the Conveyor Belt | 2250 mm (without rejector) |

| Detection System | Coil |

| Detectible Material | Carbon Steel Stainless Steel Nonferrous Alloys |

| Speed of the Conveyor Belt | 50 m/min (regulated) |

| Height up to the Weigh Carriage | 720 – 950 mm |

| Power | AC220V 50Hz |

| Power Consumption | 0.5 kW |

| Dust/Water Protection | IP 54 / IP 65 |

| Version | Stainless Steel |

*The technical specifications can differ according to the product features

Grocery Conveyor

Metal Detector

Light and Sound Alarm

Rejector

Unit for Rejects Accumulation

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

WEIGHT CONTROL AND INSPECTION OF THE PRODUCT FOR METAL PARTICLES:

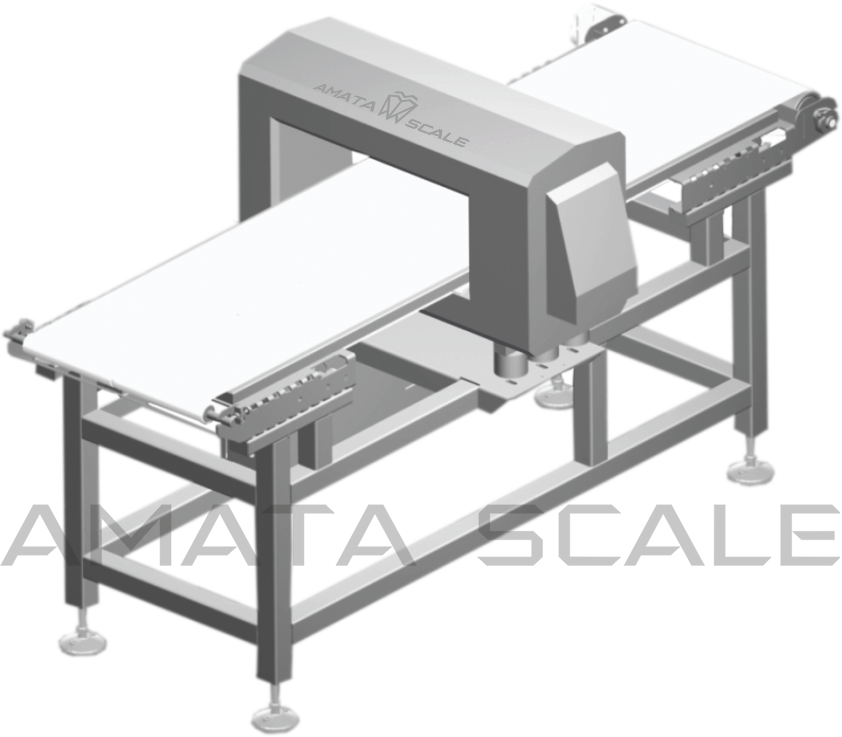

АМАТА 350MD

Conveyor metal detector is designed to detect extraneous metal objects in raw materials, semi-finished products and finished products.

The metal detector automatically scans objects on a moving conveyor belt. In the absence of metallic inclusions in the controlled product, it passes freely through the metal detector conveyor and is transferred further to the production line for further processing. Upon detection of metal objects or particles, the sound and light indication is triggered, and the object with metal is rejected.

With the help of a metal detector, the safety of products during processing and use is ensured, as well as the equipment is protected against ingress of random bodies containing magnetic and non-magnetic metals.

Various additional options can be used to receive the rejected product: a basket for collecting defects, a gravitational roller table, a rotary table, or others.

| Width of the Conveyor Belt | 350 mm |

| Height of the Controlled Object, max | 250 mm |

| Length of the Conveyor Belt | 2250 mm (without rejector) |

| Detection System | Coil |

| Detectible Material | Carbon Steel Stainless Steel Nonferrous Alloys |

| Speed of the Conveyor Belt | 50 m/min (regulated) |

| Height up to the Weigh Carriage | 720 – 950 mm |

| Power | AC220V 50Hz |

| Power Consumption | 0.5 kW |

| Dust/Water Protection | IP 54 / IP 65 |

| Version | Stainless Steel |

*The technical specifications can differ according to the product features

Grocery Conveyor

Metal Detector

Light and Sound Alarm

Rejector

Unit for Rejects Accumulation

For special equipment, the warranty period is 12 months without limiting the number of operating cycles.

For more information about the terms of warranty service, you can click here:

WEIGHT CONTROL AND INSPECTION OF THE PRODUCT FOR METAL PARTICLES: