Any industrial equipment must be protected from dust and moisture. Otherwise, electrical devices can become hazardous or just fail.

Today, the International Protection Marking (IP) is a generally accepted labeling system for protecting equipment from environmental influences. This is a classification of the method of protection provided by the shell of a technical device from access to hazardous parts, ingress of external solid objects and (or) water, and verified by standard test methods. On the territory of Russia, such a system for classifying the degrees of protection provided by equipment enclosures is regulated by GOST 14254-2015 ‘Degrees of protection provided by enclosures (IP code)’.

The degree of protection of the enclosure of electrical equipment is marked with the international protection mark (IP) and two numbers, with the optional addition of a specific letter, the first of which means protection against solid objects, the second from water penetration.

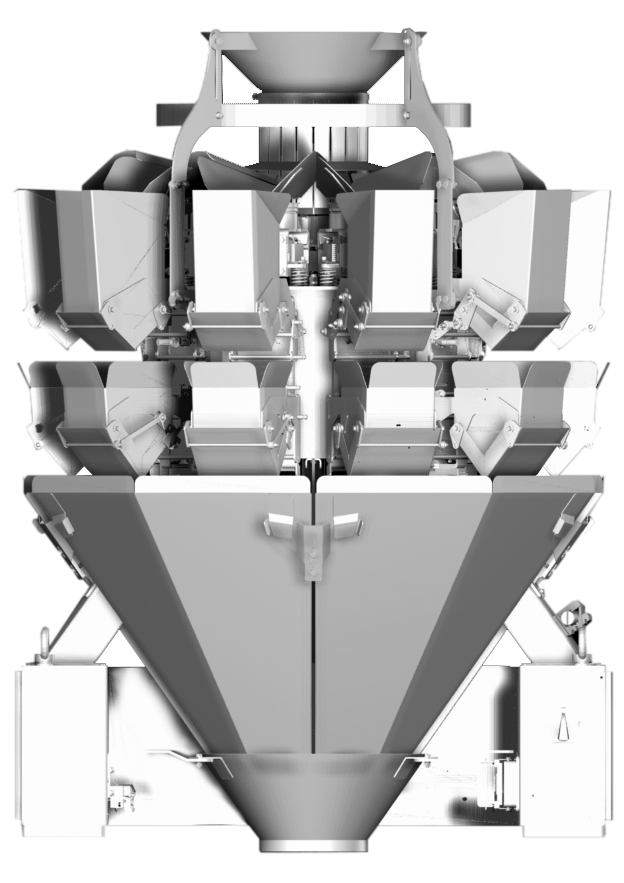

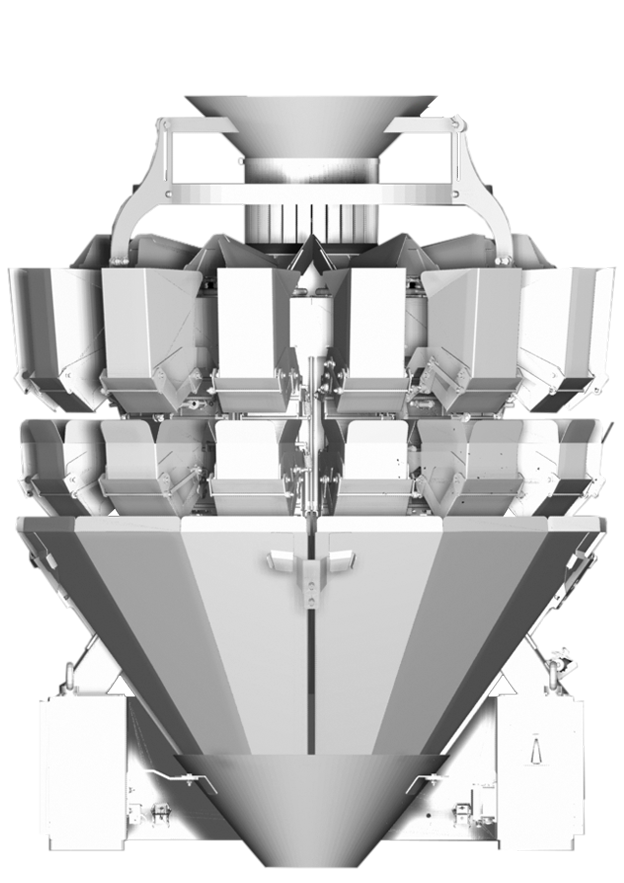

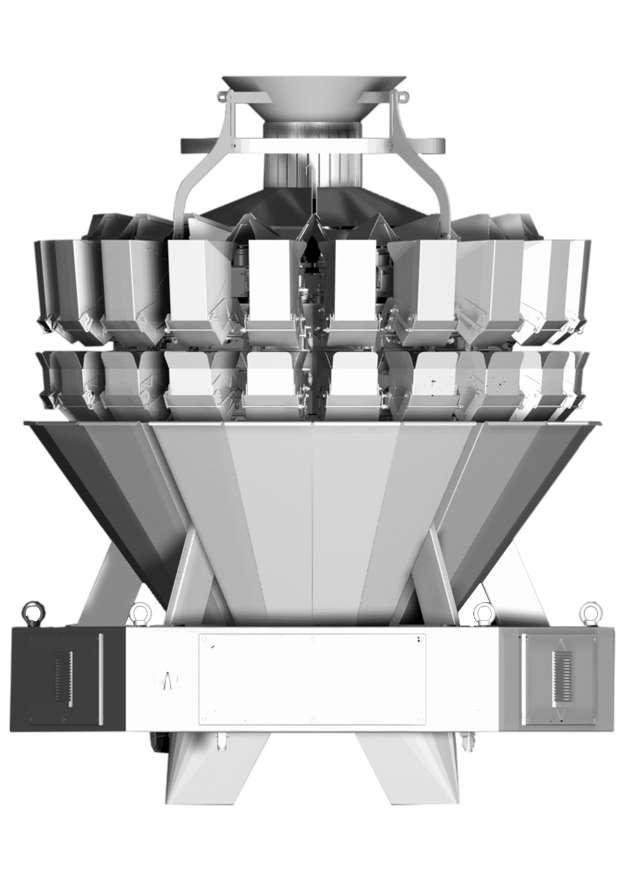

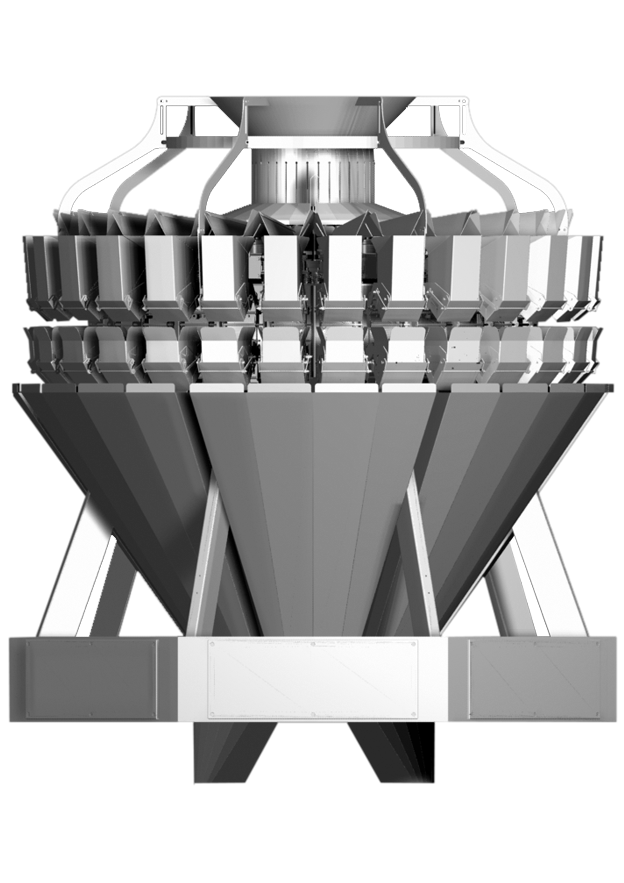

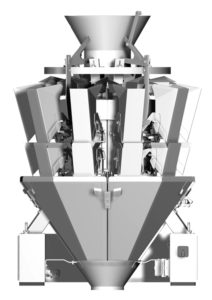

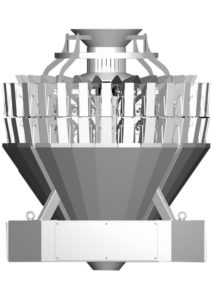

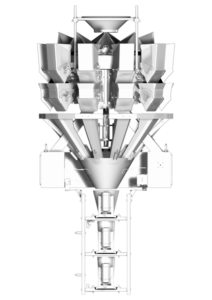

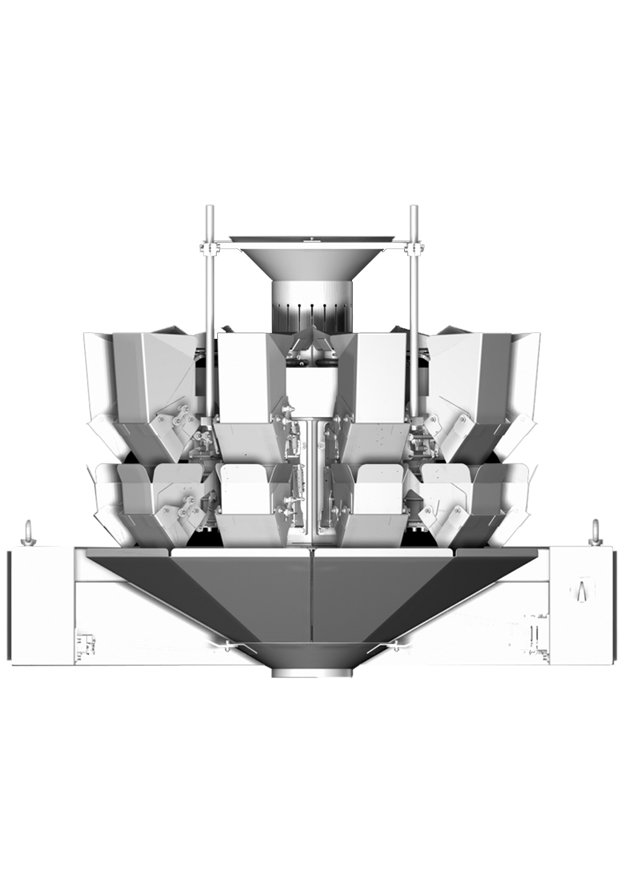

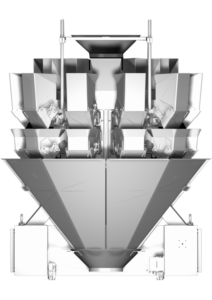

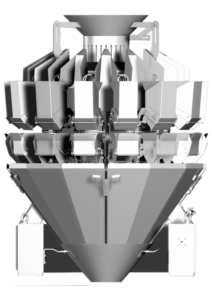

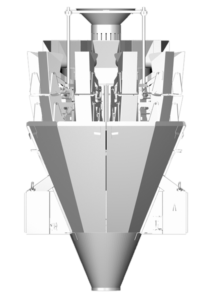

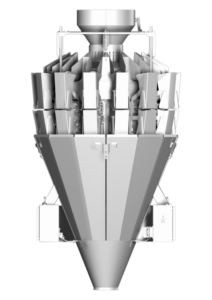

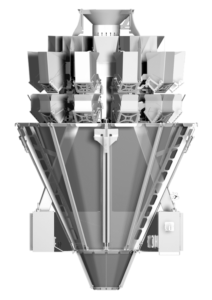

Typical AMATA equipment models typically have a degree of protection of IP 54. This means that the equipment is protected from dust and continuous splashing.

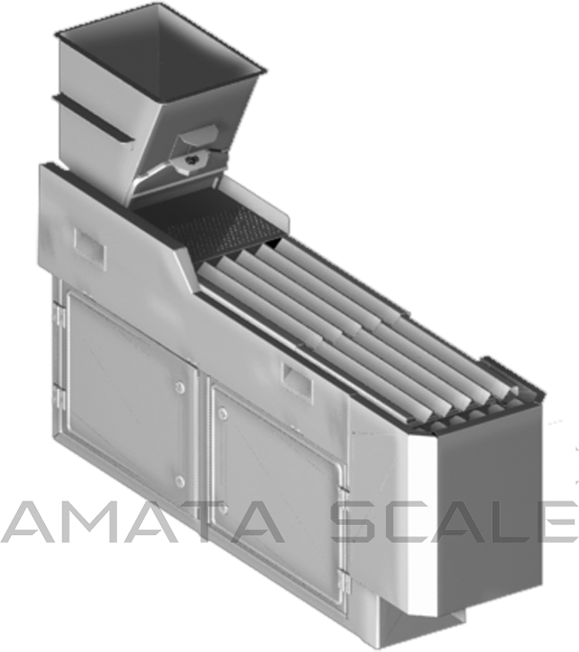

In the basic configuration, the degree of protection IP 54 extends to AMATA equipment, which is designed to work with mainly dry bulk products. The cleaning of such equipment is most often carried out using compressed air and does not imply frequent washing with water or detergent solutions.

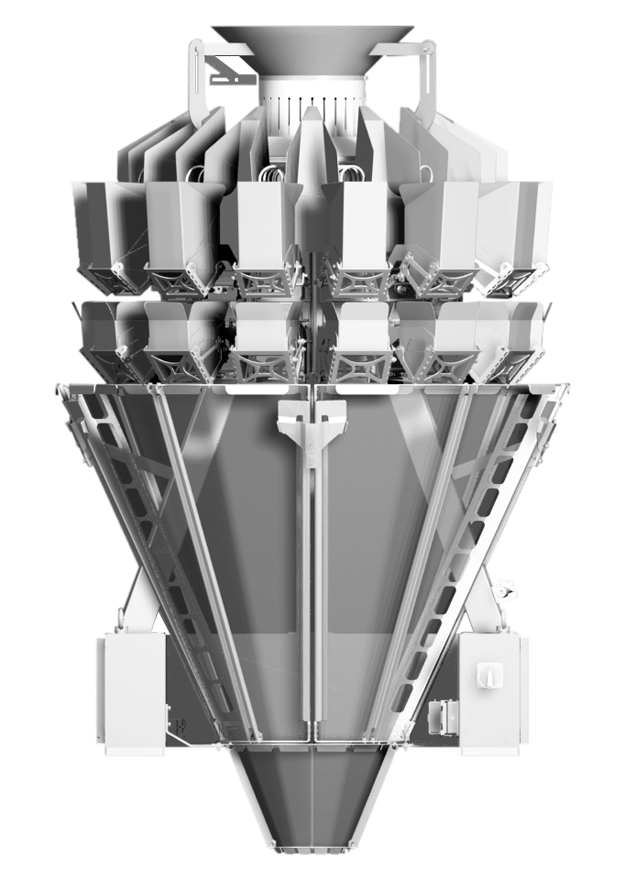

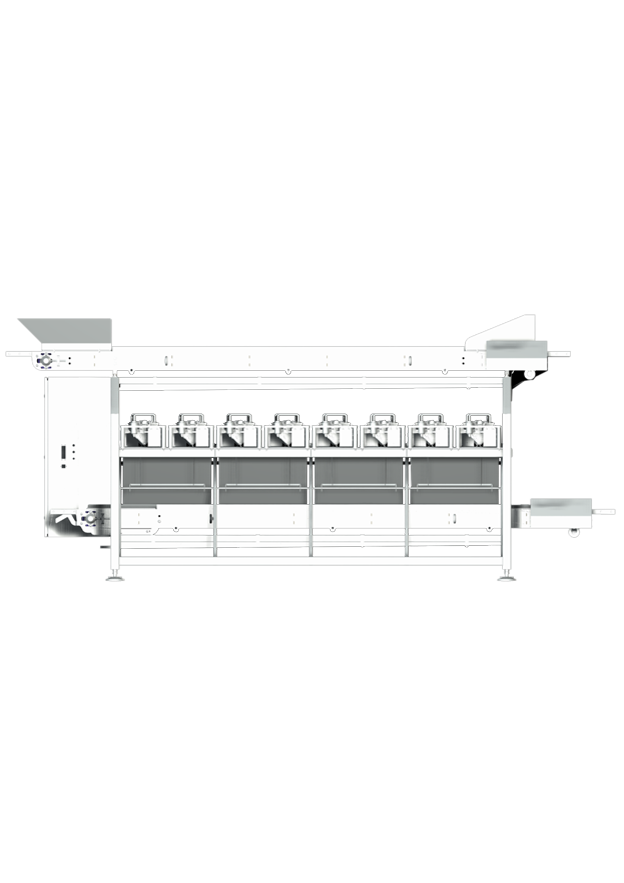

At the request of the clients the degree of protection of the specified equipment can be increased to IP 65. As a rule this is necessary when working with a fatty product, for example when packing nuts. Also increasing the degree of protection is relevant when working with frozen or sticky products. All of the described products require frequent and thorough washing of the elements of the product path, therefore, all components of the dispenser must be dustproof and protected from water jets.

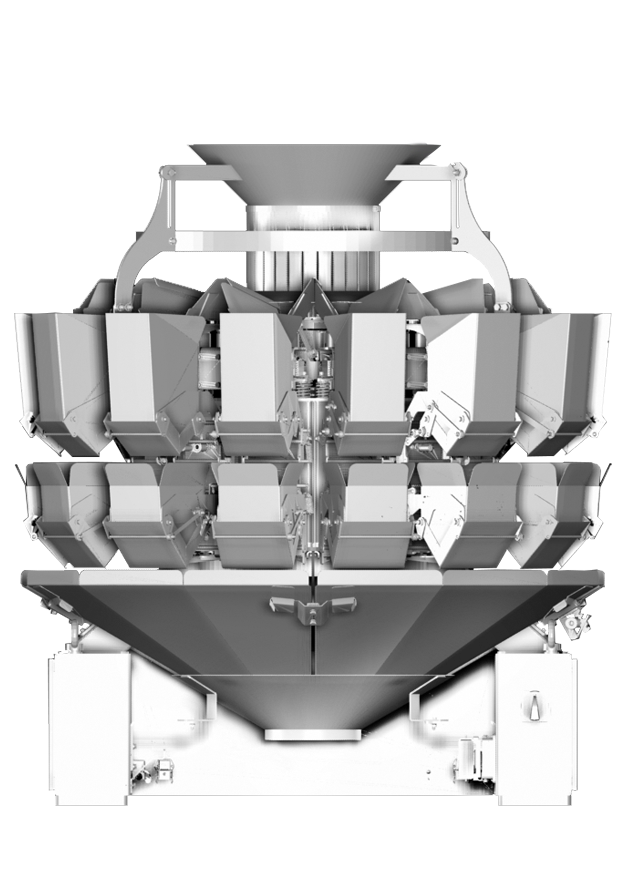

Some AMATA dispenser models already have IP 65 protection as standard. These are multiheads designed for working with specific moist foods such as crumbly cottage cheese, korean salads, sauerkraut, sticky dried fruits (prunes, dates), chilled meat, seafood and so on. Cleaning of the elements of the food tract of such dispensers should be carried out at least once per shift with the help of special detergents, therefore, for such multiheads, increased dust and moisture protection are necessary.

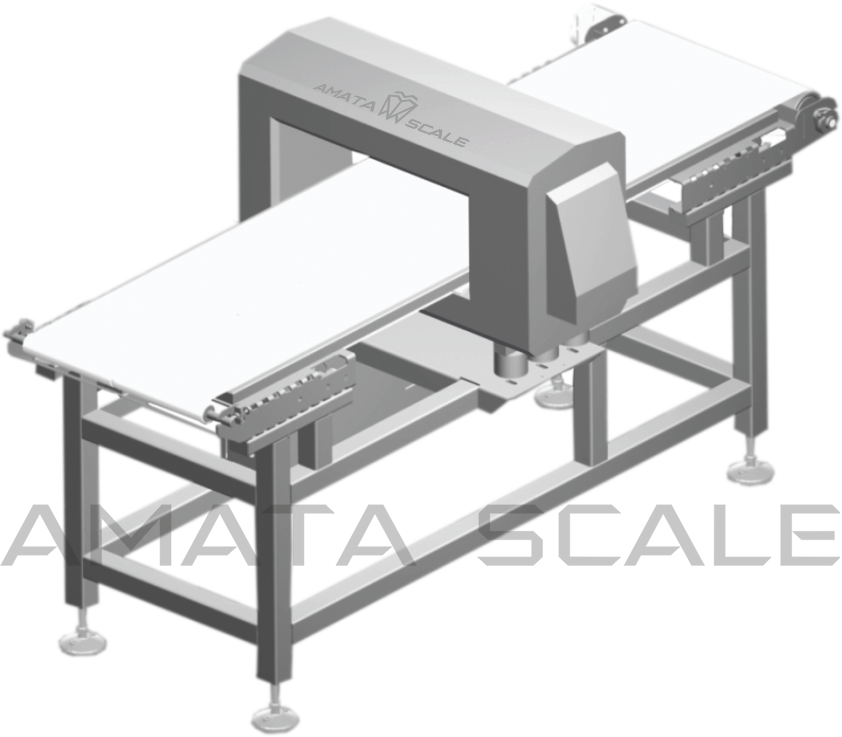

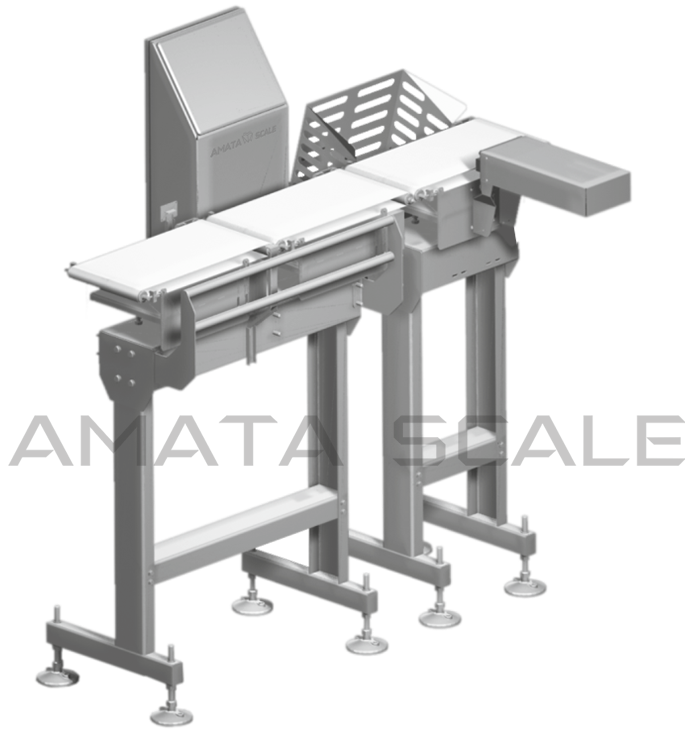

AMATA control equipment as standard is not equipped with additional degrees of protection. However, sometimes the specifics of the products used dictate special requirements and at this stage check both for the presence of metal and for weight. This often concerns the physical characteristics of the surface of the product: whether it is dry or sticky, how wet. In the first case, it is preferable to apply the degree of protection IP 54, when it is recommended to strengthen the equipment specifically IP 65 for wet products. In addition, the method of cleaning and washing equipment is not of the last importance: in the case of regular treatment with wet cleaners, the equipment must be equipped with IP 65 protection. In some cases, it is not necessary to strengthen the control equipment with protection.

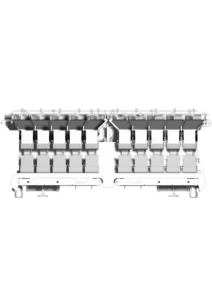

Depending on the wishes and needs of the client the type of product and its features, production specifics, as well as methods of water treatment, washing and cleaning of equipment, IP 54 or IP 65 protection degrees can be equipped with AMATA control equipment: conveyor metal detectors and dynamic scales (checkweighers)

Contact our managers and learn more about the capabilities of the AMATA equipment, including more suitable options for the degree of protection specifically for your company and type of product:

- phone: +7 (812) 320-42-01

- e-mail: info@amatascl.com